With press and articles in mind, we are starting to make, assemble and put up our outdoor signage and logo. It won’t be long until we open officially in May, although we have in reality been open for fit-out volunteers for a while. We are now starting to make contact with other clubs or societies with a mutual interest in our facilities and generally get the press campaign moving along, so having a finished signage will make a great backdrop for any photo opportunities.

If you haven’t caught our previous article about it then you can read more here.

Logo Signage

A quick CAD mockup to show roughly what we are after. A nice welcoming arrow pointing you into an even nicer welcome inside.

Like with everything else, a whirlwind of Damian later and the mockup started making it physical. This is Damian btw, the master chippy, any plywood or stud (?) work and he’s your man.

The tile mounting board was cutout, painted black and mounted on a contrast background. More taggers make their mark on the whiteboard too.

Tiles that are in our possession are assembled onto the logo and assembled onto the main signage. Follow our Tile of the Day tweets @swindonmakers for updates when more come in.

We have some more finishing to do and some coloured LED backlit strips to install for that final bling.

Lettering

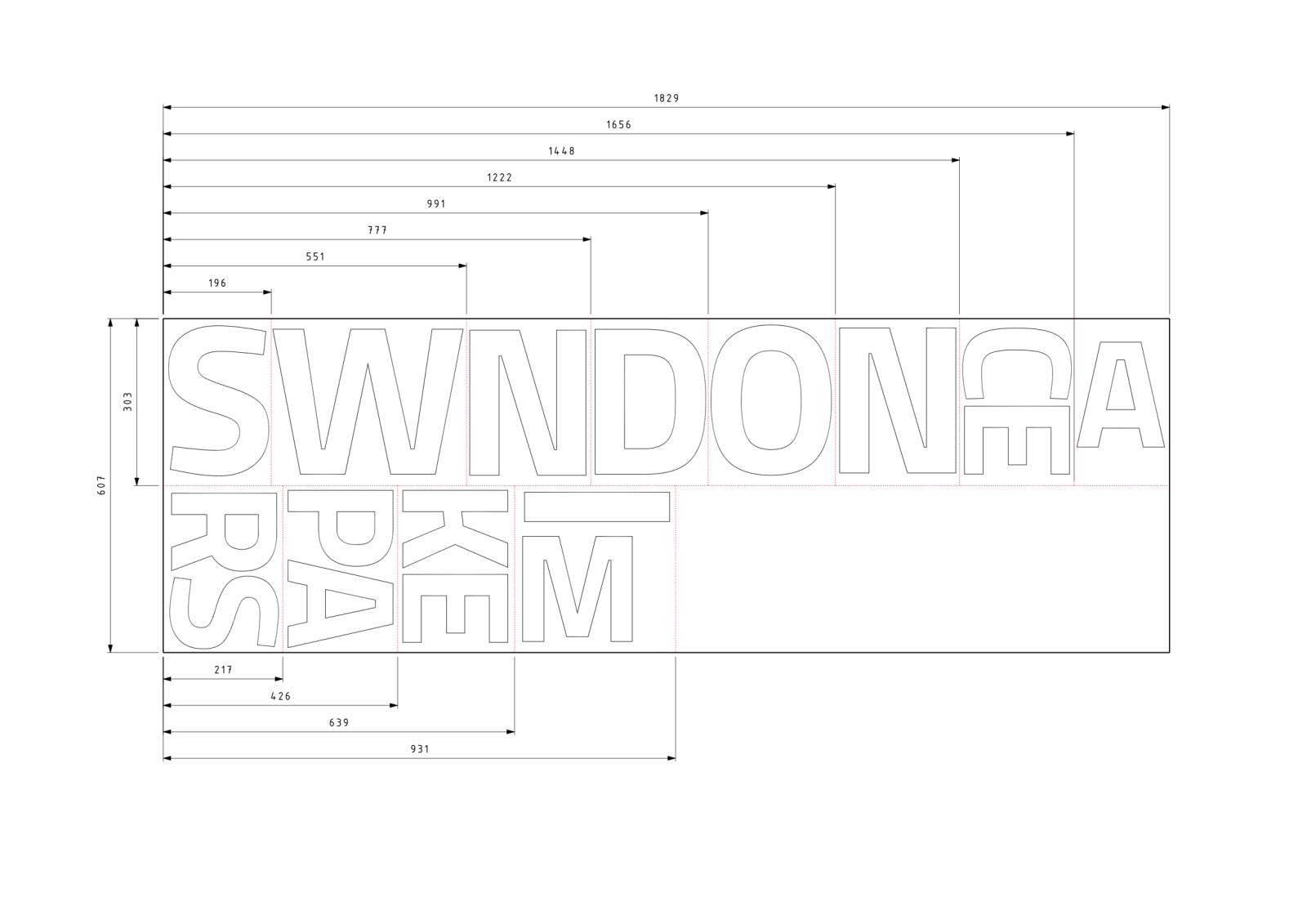

The lettering is written in our favourite Titillium Web font except it has gone large somewhat. We pondered whether to cut out the letters by hand from plywood to a paper template and offload some of that work between several members. However after a vote it was 100% agreed that I would machine them from plywood on my CNC router, that will teach me for offering.

First thing is to place the letters on a cutting layout to choose the best fit and orientation and keep waste to a minimum. Next I to cut the large board into the smaller pieces (red) so I could fit each blank within the limits of my routing machine.

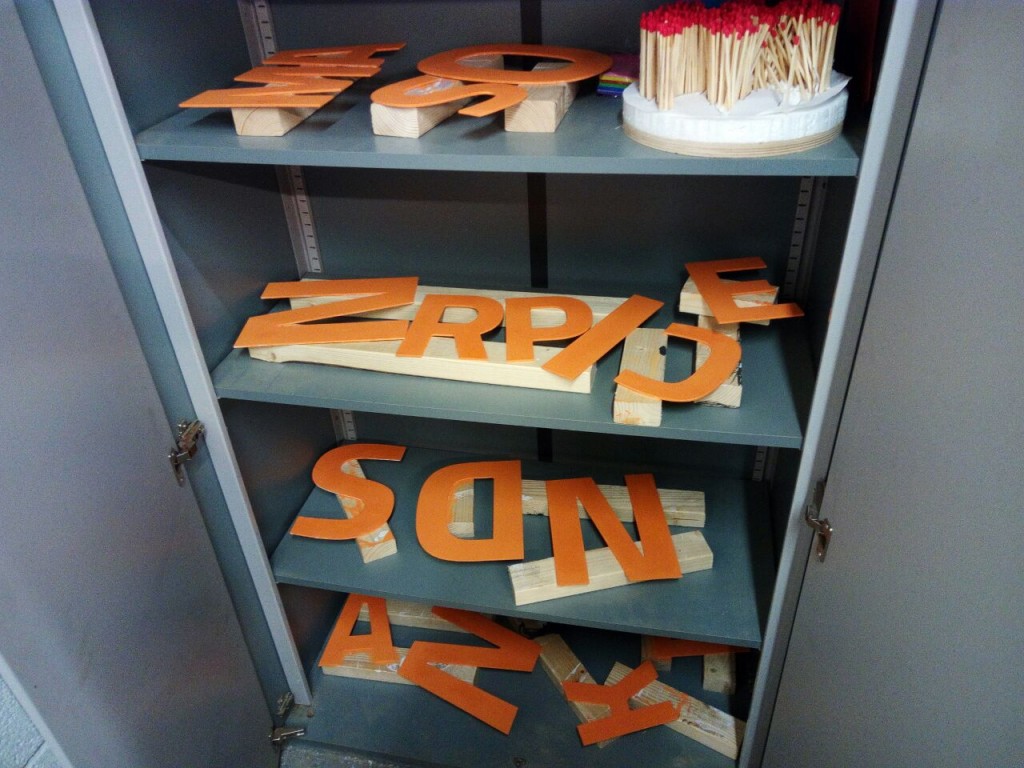

Using Linux CNC controller and a dia 3mm slot drill, I began to make lots of smaller bits of wood. The plywood is fixed to the base board by double sided carpet tape.

Once all the letters were machined, we undercoated them and are currently in a state of top coat drying.